Stan-Cor ANSI Centrifugal Pumps

Tel (612) 332-5681

Email: sales@wannereng.com

Wanner Engineering, Inc.

1204 Chestnut Avenue<br>Minneapolis, MN 55403 USA

Stancor Pumps Principles of Operation

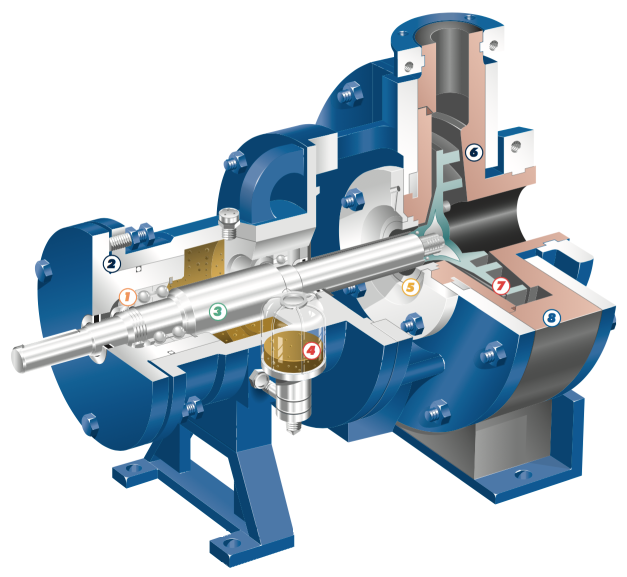

Heavy-duty Bearings

Stan-Cor’s duplex angular contact thrust bearings in the rear withstand far greater radial and axial thrust than conventional bearings.

Bearing Housing

External adjustment of rear bearing housing is used to set impeller clearance ensuring zero end play for maximum mechanical seal life.

Optimized Shaft Design

Optimized shaft design features maximum diameter-to-length ratio, minimal overhang, and extra heavy-duty support to minimize shaft de ection and associated seal wear.

Oil Bath Reservoir

Oil bath reservoir with over ow sight glass keeps bearings fully lubricated.

Seal Options

Component and cartridge seal options available.

Bearing Housing

Kynar 370, a carbon-filled PVDF material is thermally stable to maintain tight dimensions.

Impeller

Molded from solid Kynar 370, Stan-Cor semi-open tapered impellers are machined to the exact diameter required to control performance. Additional back pump out vanes produce low stuf ng box pressures and keep seal area clear of debris.

Casing

Stan-Cor pumps have a concentric casing (see illustration below), which greatly reduces turbulence and vibration, extends seal and bearing life, eliminates excessive hydraulic imbalances and allows the pump to run anywhere between a few gpm to maximum ow without undue shaft de ection. The design allows the Stan-Cor pump to handle abrasives much better than standard open impeller centrifugal pumps.

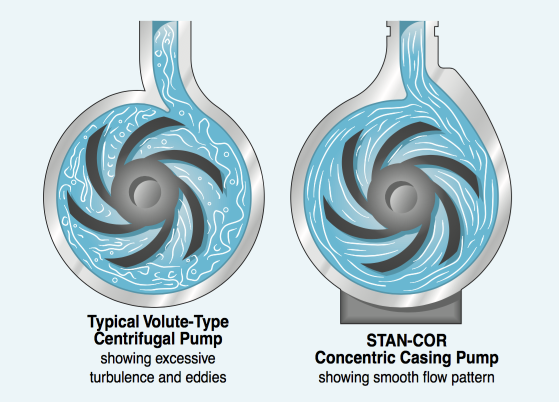

Stan-Cor Patented Concentric Casing Advantages

Unlike volute-type centrifugal pumps, the Stan-Cor pump uses a unique concentric design that provides a constant, equal distance between the pump casing and the impeller at all times during pump operation. This greatly reduces turbulence and vibration, thereby extending the life of the mechanical seal and bearings.

In a conventional volute casing pump, water turbulence and eddies are created as the impeller passes the restrictive cut water area in the casing. These hydraulic imbalances in turn cause the drive shaft to de ect, which increases the loading on the bearings, and leads to premature mechanical seal failure. At near shut-off, the bearing loading is extremely high.

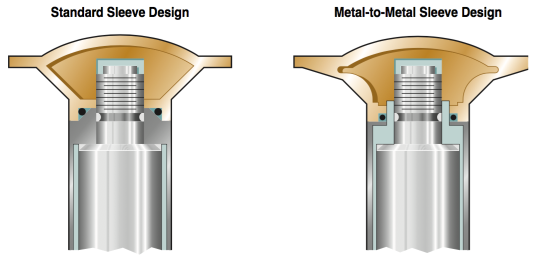

Metal-to-Metal Impeller/Shaft Sleeve

For strenuous pump applications in which the pump undergoes excessive cavitation or in which the pump is allowed to “run off the curve” because of low head and high ow requirements, the MTM option provides the added impeller stability to help avoid the possibility of excessive impeller de ection.

If occasional conditions as described earlier occur in the application, the MTM design option should be considered to help protect the pump from damage during the occurrences. The MTM design will not stop the effects of cavitation, but it can protect the pump from damage for a period of time. System problems that lead to these occurrences must still be resolved.

On the standard Stan-Cor Kynar pump design, the drive shaft is protected by a Kynar-encased sleeve that threads directly into the impeller hub.

An o-ring seals the area between the Kynar of the impeller and the Kynar of the shaft sleeve to ensure that corrosive process uids do not come into contact with any metallic parts.

For added protection on demanding applications which utilize impellers over 9” in diameter, the Stan-Cor PST-A60M, PST-A30 and PST-A40 can be fitted with an optional MTM impeller/sleeve design in which the metal insert of the shaft sleeve extends around the drive shaft.

When the shaft is threaded into the impeller and tightened, this sleeve extension forms a solid metal-to-metal contact with the impeller hub for added impeller stability.

The Stan-Cor Concentric Casing Design

The Stan-Cor concentric casing design eliminates these excessive hydraulic imbalances.

- It allows the pump to run anywhere between a few gallons per minute and full ow without undue shaft deflection.

- Moreover, the design allows the Stan-Cor pump to handle abrasives much better than standard models.

The sharp, restrictive cut water area of most pumps is the focal point for corrosion and erosion. It is the place where abrasives first attack a pump. With lined pumps, the thin liner is easily abraded away and the metallic backing exposed to the corrosive and abrasive forces of the product being pumped.

The Stan-Cor concentric casing design, coupled with its solid homogenous non-metallic component, eliminates this problem area.